Rubber consists of long and flexible macromolecules, which are physically entangled. During processing, raw rubber is mixed with fillers and processing agents. The raw product is vulcanized at elevated temperature and pressure to form cross-links between the macromolecules. The cross-link density correlates with the transverse NMR relaxation time T2, which can be estimated with the NMR-MOUSE at different positions and depths in the intermediate and final rubber products. The type and quality of raw rubber can be controlled with a Spinsolve spectrometer by 1H NMR spectroscopy of the raw product dissolved in a solvent like chloroform.

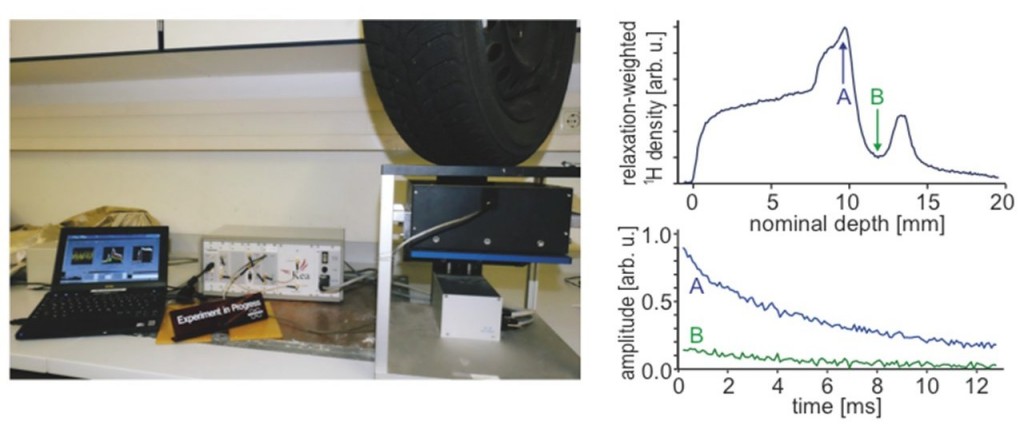

The figure above shows the depth profiling with the NMR-MOUSE. Left: Photograph of the NMR-MOUSE PM25 measuring a depth profile through a winter tire mounted on a steel rim. Right, top: Depth profile through the tire tread. The amplitude is a relaxation weighted proton density corresponding to the grey scale in a magnetic resonance image. The depth scale is distorted by the presence of the steel belt. The signal decays at positions A and B differ in their amplitudes as well as in their decays corresponding to different T2eff.

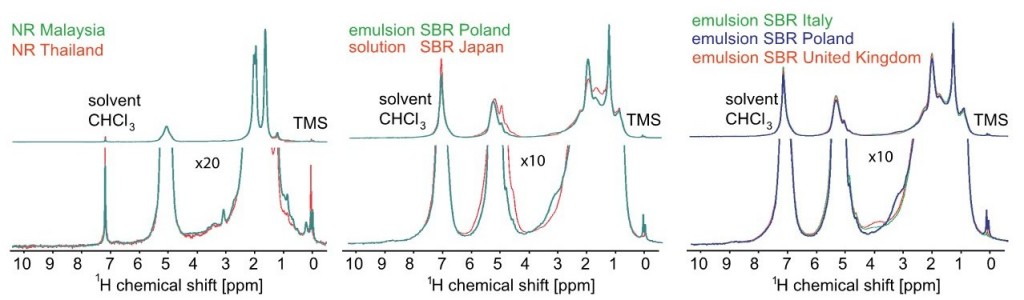

The Spinsolve 1H NMR spectra of rubber dissolved in deuterated chloroform are shown without (top) and with (bottom) magnification. Left: NR from different plantations. Middle: Comparison of emulsion and solution SBR. Right: Comparison of emulsion SBR from three different manufacturers.

You can download a PDF file about Compact NMR for Tyre and Rubber Testing.