634. Use of an internal loop airlift bioreactor to produce polyhydroxyalkanoates by Stenotrophomonas rhizophila

Berenice Clifton-García, Juan Villafaña-Rojas, Orfil González-Reynoso, Jorge Ramon Robledo-Ortiz, Ricardo Manríquez-González, Porfirio Gutiérrez-González, Yolanda González-García, ChemIndChemEngQ, (2025), DOI: 10.2298/CICEQ230819014C

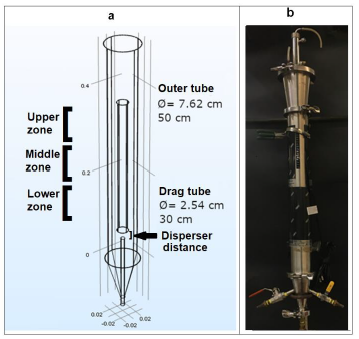

Airlift-type bioreactors present advantages over conventional systems such as efficient mass transfer, simplicity of construction, and low energy consumption. Thus, they are a good alternative for the production of polyhydroxyalkanoates (PHAs) nevertheless, their use for that purpose has been barely studied. This work addresses the design, construction, and hydrodynamic characterization of a 2.4 L internal loop airlift bioreactor, evaluating the effect of the airflow, liquid volume, and disperser position, on the interfacial area and the mixing time. Then, it was used for the fed-batch production of PHB by Stenotrophomonas rhizophila from sugar cane molasses. It was found that the conditions to increase the interfacial area and minimize the mixing time were: airflow of 1.5 vvm, liquid volume of 2400 mL, and disperser position of 5 mm (distance between the air disperser and the drag tube). Under that configuration, the maximum biomass concentration, PHB production, and PHB accumulation achieved (54 h of culture) were 65.4 g/L, 39.9 g/L, and 60.2 % (g of PHB/100 g dry biomass), respectively. The polymer was poly-3-hydroxybutyrate, with a melting temperature of 170°C, crystallinity of 56.4 %, and a Mw of 735 kDa.